Today in the United States, Texas customers want to buy 3000w fiber laser plate cutting machine, he is very hesitant, on the one hand, he does not know the machine very well, on the other hand in the performance match (cutting capacity and processing needs to match) can cut

how thick? How fast? What materials are suitable for (carbon steel, stainless steel, aluminum, etc.)? Does it support cutting pipes and plates? Does it support multiple shapes or customized parts? After-sales service and technical support? As well as transportation and installation, etc. are all in doubt.

In response to these questions, in order to better enable our customers to dispel doubts, we summarize this series of questions and answer them one by one. (Take 3000w flatbed laser cutting machine for example)

1. Laser

Adopts high performance fiber laser (such as IPG, Rike, etc.), 3000W power balance efficiency and cost, suitable for medium-thick plate cutting.

Optical and electrical conversion efficiency > 30%, low energy consumption, life expectancy of up to 100,000 hours.

fiber laser cutting machines MAX Laser

2.Cutting head

High-precision capacitive cutting head, automatic focus function, adapt to different material thickness (such as 0.5-20mm carbon steel).

Anti-collision protection is standard, reducing maintenance costs.

fiber laser metal cutting machine

fiber laser metal cutting machine cutting head

3.CNC system

Equipped with Patron, PA or Siemens system, supports graphic import, automatic nesting, intelligent perforation and easy operation.

fiber laser cutting machine for metal Operation interface

4.Machine structure

Fully enclosed protection/open design, optional exchange table to improve the efficiency of continuous operation.

e.g.:

Fully enclosed exchange table fiber laser cutting machines

Laser cutting machine bed

Q2: Performance Matching (Matching Cutting Capability to Processing Needs)

Many of our customers come from agricultural equipment, oil and gas structures, and heavy manufacturing industries, which have high requirements for thick plate/thick tube cutting capability. Our

3000W fiber laser cutting machine is designed to meet the high standard needs of heavy industrial customers in Texas, with the following performance:

1. Excellent cutting capacity and speed

These properties allow the equipment to excel in handling thick plates and tubes, making it particularly well suited for the heavy fabrication and oil and gas structures industries in the Texas area.

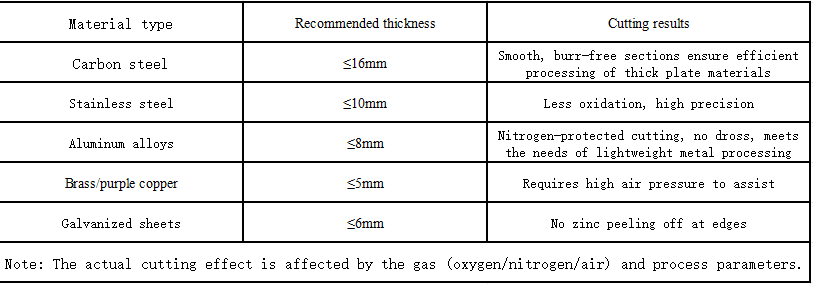

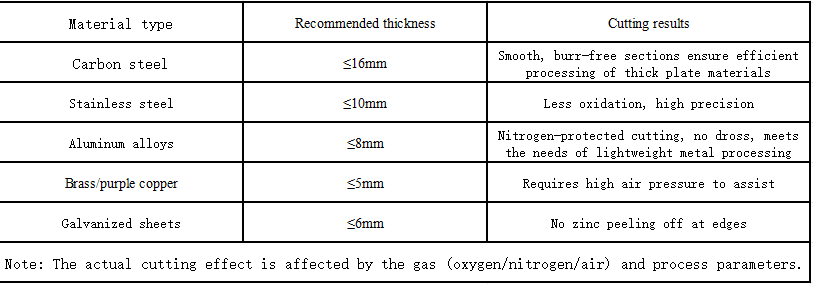

2. Wide range of material adaptability

Supports cutting a wide range of materials, including:

•Carbon steel: suitable for processing structural parts and frames.

•Stainless steel: widely used in food processing, chemical equipment and other fields.

•Aluminum alloy: suitable for aerospace, automotive parts and other industries.

•Copper and brass: used in the manufacture of electrical and electronic components.

This gives the equipment a wide range of applications in various industries.

Carbon steel cutting sample

►Industries and applications of laser cutting machines

•Sheet metal processingEnclosures and cabinets, elevator panels, ventilation ducts, etc., efficiently replacing traditional punching machines.

•Automobile ManufacturingBody parts, exhaust pipes, suspension parts, etc., with an accuracy of ±0.1mm.

•Construction MachineryThick steel plate cutting (e.g., excavator boom), bevel cutting is optional.

•Home Appliance IndustryStainless steel panels, metal casings, high consistency in mass production.

•Advertising and decorationMetal characters, artistic hollow parts, support complex graphics cutting.

•New EnergyPhotovoltaic bracket, battery box, compatible with aluminum cutting.

3. Multi-functional cutting ability

Pipe cutting function: support the cutting of round, square, rectangular, elliptical tubes and other tubes to meet the processing needs of complex structural parts. (There are fiber laser pipe cutting machine/fiber plate and pipe integrated machine recommended)

Plate cutting function: applicable to the cutting of flat plates, providing a wider range of processing options. Customized Shape Cutting: supports cutting of multiple shapes and customized parts to meet special design requirements.

3kw fiber laser cutting machine price

♦3KW Plate Fiber Laser Cutting Machine Cost-effective

3000W power covers 80% of medium and thick plate requirements, with a short payback period for equipment investment (example: 20% lower cost than 4000W model).

•Intelligent featuresRemote monitoring, fault diagnosis, process database, reducing operator dependence.

•Environmental protection and energy savingNo consumables (compare with plasma), noise <80dB, in line with green factory standards.

•Customized serviceOptional automatic loading machine, dust removal system, to adapt to different production line needs.

4. Adapting to the needs of the Texas industry

Texas, as a center of heavy industry and the energy industry, has high standards for the ability to cut thick plates and tubes. Our equipment excels in these areas, meeting the processing needs of the Texas agricultural equipment, oil and gas structures, and heavy fabrication industries.

Are there any local technical service locations in Texas or the US?

Do you provide free training? Are there any English operation manuals, remote diagnosis and other services? How long is the parts warranty? How long will free support be provided?

►Local Support That Makes a Real Difference

We don't just sell equipment, we value it every day after it runs. As a local brand in Texas, we promise to provide fast, professional and reliable after-sales service for our customers:

•Localized Service Team

Headquartered in Texas, with local maintenance service points

Engineers are available to come to your home at any time for maintenance, so as to avoid delaying the production due to the waiting for the overseas technology

The transportation machinery team of Texas, USA

• Free Training and Full Set of Material Support

Provide free on-site or remote training (full coverage of installation, operation, and daily maintenance) )

Chinese and English operation manuals, maintenance manuals, video teaching materials

• Remote diagnosis + technical support

Support remote equipment diagnosis, system debugging and upgrading through the network

Rapid response to after-sales problems by phone, video, reducing downtime

• After-sales warranty and continuous service

1-year warranty for the whole machine, up to 2-year warranty for the laser

Lifetime technical support, long-term local service guarantee in Texas

Long-term stocking of key components, fast delivery and quick replacement

Q4: Shipping & Installation Advantage: buy with peace of mind, install with peace of mind

► Worried About Delivery & Installation? We've Got You Covered - Locally in Texas!

As a Texan As a local laser equipment supplier in Texas, we provide full-process localized services, so that our customers have zero worries:

✅ In-stock supply, very fast delivery

Local stock inventory in Texas warehouse, no need to wait for international shipping.

Shipments as soon as 48 hours after the order is confirmed, without delaying the production schedule.

fiber laser metal cutting machine/Support customization for various machine sizes and powers

✅ Free delivery

Support Texas-wide home delivery service.

Flexible arrangements with the factory's delivery time to save customers manpower and logistics coordination costs. Save customers' labor and logistics coordination costs.

(Bonus services worth over 500,000 US dollars)

✅ Include installation services, engineers to debug

Provide professional door-to-door installation and debugging services, without the need for customers to find additional people to install.

The team of experienced engineers to ensure that the equipment is stable before handing over.

✅ Bilingual technical team, assisting the whole process Local resident engineer Bilingual technical team to assist in the whole process

Local stationed engineer team to support English and Spanish services.

Operational training + maintenance guidance in place at once, to ensure that the customer quickly put into production.

✅ Experienced in the transportation of large equipment

We are familiar with the process of transporting large equipment, and we arrange professional equipment lifting/installation.

Provide pre-transportation communication drawings, site survey recommendations, to help customers to plan the location of the installation in advance.

Luminary Laser service process

If you have any questions, please feel free to contact us

Related product recommendations:

♦ Steel Structure Laser Cutting Machine

♦ Large Size Fiber Laser Cutting Machine

♦ Fully Enclosed Dual Platform Fiber Laser Cutting Machine

♦ Basic High Power Fiber Laser Cutting machine